Counter Flow Drum Mix Plant (60-120 TPH)

Forget your conventional old technology drum mix plant and switch to our new Technology COUNTER FLOW DRUM MIX PLANT with THERMIX DRUM with upto 30% RAP addition.

Introduction

Asphalt is the backbone of modern road construction, and the quality of asphalt used directly affects the durability and safety of roadways. Counterflow asphalt plants are revolutionizing the way asphalt is produced, making it more efficient and environmentally friendly. In this article, we will take a closer look into the workings of counterflow asphalt plants, their advantages, applications, components, maintenance, and much more.

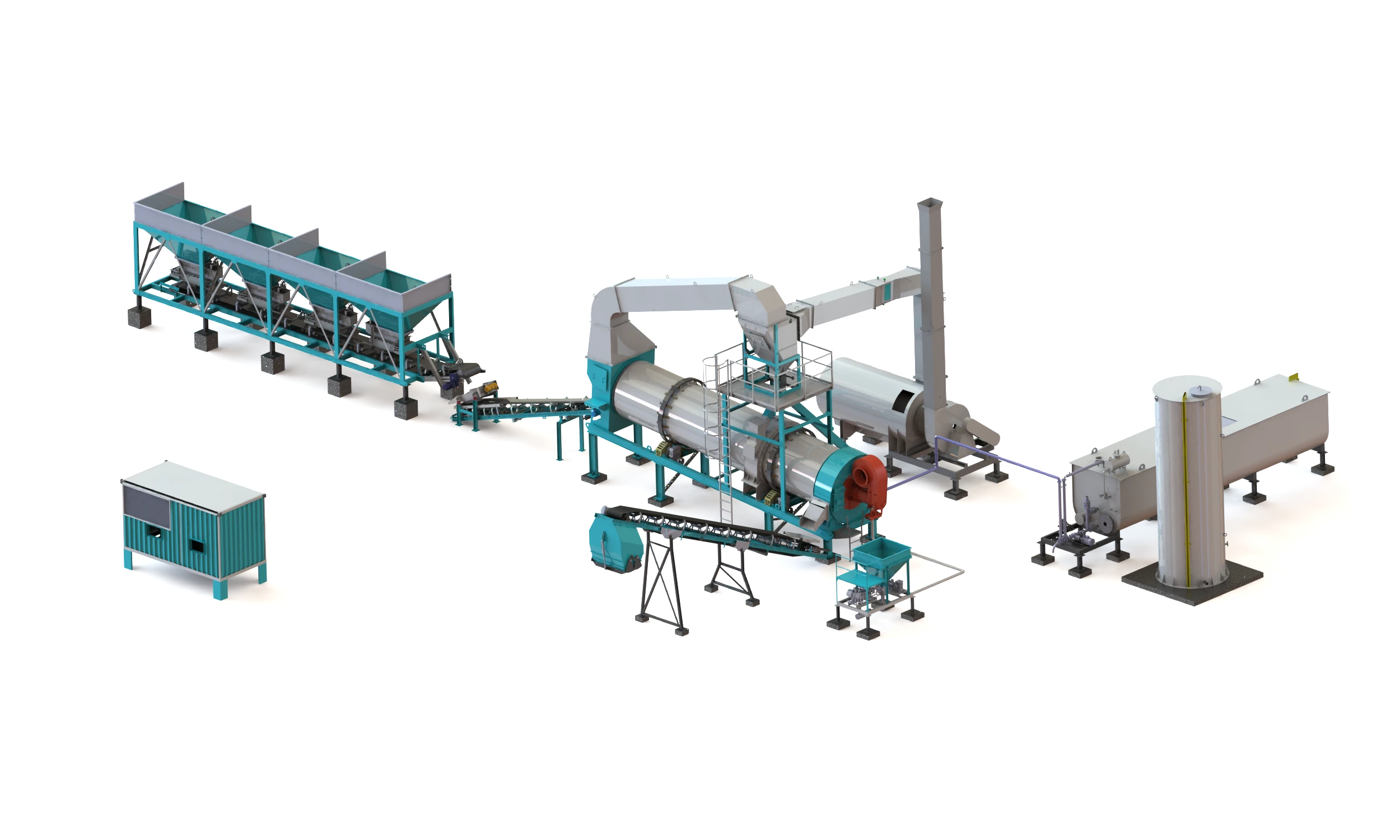

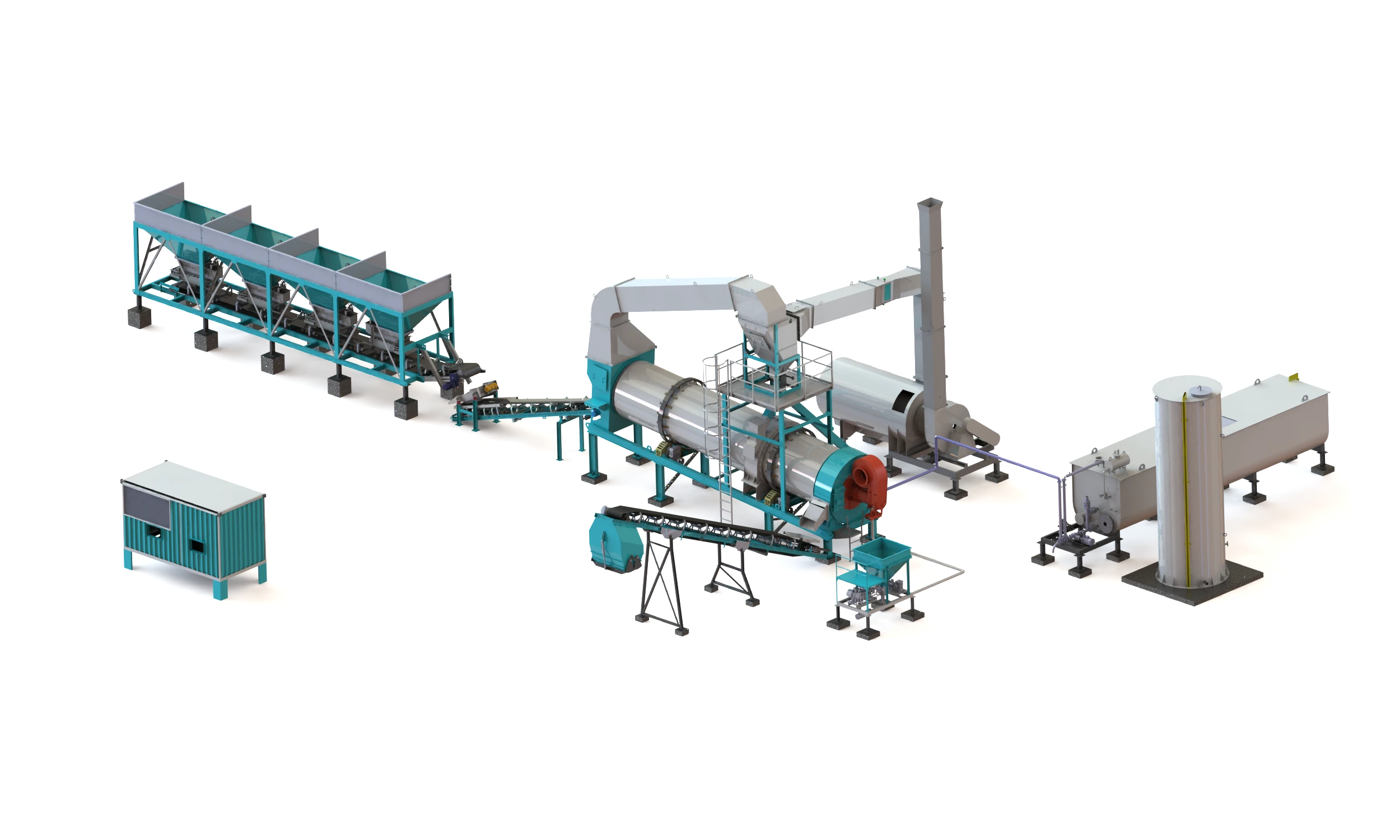

Cold Aggregate Bins

Slinger Conveyor

Dryer Drum

Control Cabin

Gob Hopper

Load Out Conveyor

Long Nose Dryer Burner

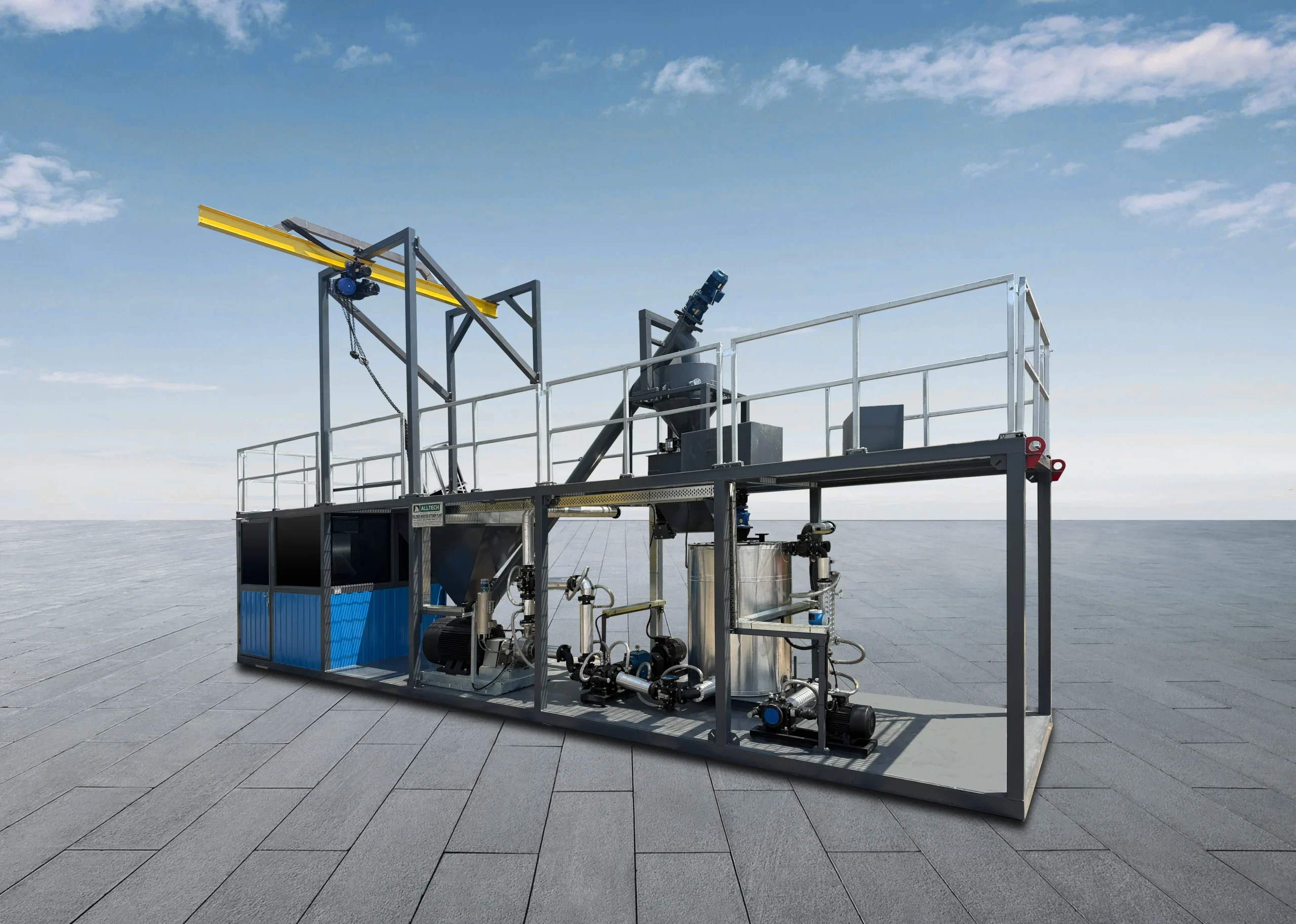

Mineral Filler Unit

Fuel Tank

Bitumen Tank

Venturi Type CV

(Wet Scrubber Unit)

Cold Aggregate Bins

Slinger Conveyor

Dryer Drum

Control Cabin

Gob Hopper

Load Out Conveyor

Long Nose Dryer Burner

Mineral Filler Unit

Fuel Tank

Bitumen Tank

Venturi Type CV

(Wet Scrubber Unit)

Technical Specification

| PLANT TYPE | CFD 90 (60-90 TPH) | CFD 120 (90-120 TPH) |

| PLANT CAPACITY @ 3% MOISTURE | 90 TPH | 120 TPH |

| PLANT CAPACITY @ 5% MOISTURE | 70 TPH | 100 TPH |

| NO. OF COLD FEEDERS | 4 | |

| COLD FEEDER CAPACITY (With Extension Plates) | 8 m3 | 8.5 m3 |

| GATHERING CONVEYOR BELT AND DRIVE | 550 x 3.75 KW | 600 x 3.75 KW |

| BIN VIBRATOR MOTOR | 0.18 KW | |

| SLINGER CONVEYOR BELT AND DRIVE | 550 x 3.75 KW | 600 X 3.75 KW |

| DRYER DRUM TYPE (‘THERMIX DRUM’) | Cylindrical, Inclined Counter Flow Type with RAP Ring | |

| THERMIX DRUM (L X D) | 7.5 X 1.6 m | 8.5 X 1.8 m |

| DRUM DRIVE | 7.5 KW x 4 | 7.5 KW x 4 |

| MODULATING BURNER OUTPUT | 10 MW (Long Nose Burner) | 14 MW (Long Nose Burner |

| POLLUTION CONTROL BAG HOUSE | ||

| FILTER CAPACITY | 31000 m3/hr | 33500 m3/hr |

| FILTER SURFACE | 260 m2 | 290 m2 |

| EXHAUSTER CAPACTIY | 55 KW motor with VFD Drive | |

| LOAD OUT CONVEYOR CAPACITY | 200 TPH | |

| LOAD OUT CONVEYOR BELT WIDTH | 600 mm | |

| LOAD OUT CONVEYOR DRIVE | 5.5 KW | |

| GOB HOPPER CAPACITY | 1.5 MT | |

| HYD POWER PACK | 3.75 KW | |

| FILLER UNIT | Mineral Filler Unit of Capacity 1.5 m3 | |

| OPTIONAL ITEMS : | ||

| BITUMEN TANK | 30 MT Horizontal type Direct Heating/ Indirect Heating | |

| VENTURI TYPE DUST COLLECTING UNIT | ||

| EXHAUSTER CAPACITY | 22.5 KW | 37.5 KW |

| HOT MIX STORAGE SIL | 25-50 MT | |

| RECYCLING ADDITION | Through RAP addition ring in the drum. | |

Advantages

| Advantage | Old Drum Mix Plant | Counter Flow Drum Mix Plant | Benefits |

| Technology | Old technology in which heating and mixing occurs at same place. | New technology in which mixing zone and heating zone are at different places in same drum. | Viscosity of bitumen as well as properties of mixed aggregate doesn’t get affected. |

| Recycled Material | Facility to add RAC is not available | RAC can be added upto 30% | Recycled material can be used |

| Filler | Filler cannot be added | Filler can be added directly into mixing zone via RAP Collar | Filler material can be used to produce homogenous mix |

| Pollution | Only Venturi Type Dust Collector is provided for pollution control which requires large area for Dust Collection | Pollution Control Bag House is provided which ensures pollution free operation of plant | Pollution Free plant |

| Hot mix quality | Hot mix quality gets deteriorated since mixing and heating occurs at same place | Homogenous Mixing since mixing zone and heating zone are separate | Gets Homogenous mix |

| Dryer Drum | Parallel flow heat transfer which deteriorates the properties of mix as well as bitumen | Counter Flow heat transfer with mixing zone behind the burner and attached RAP Collar provides homogenous mix | Filler, RAP can be added and mixing takes place behind the burner flame |

| Fuel Consumption | Consumption of Fuel is more | Consumes less fuel as compared to drum mix plant | Less Fuel Consumption leads to cost saving of fuel |

RAP Addition - Efficiency Burner - Separate Mixing Zone

Efficient RAP Addition

High Efficiency Burner

Separate Mixing Zone

Alltech’s Thermix drum allows efficient RAP addition of upto 30% into the drum by the help of the RAP Coller.

Drying drum is equipped with a modulating long nose burner, which results in increased efficiency and low emission levels.

Thermix Drum heats up the aggregates in the heating zone and the mixing with bitumen is done in a separate mixing zone to provide homogenous mix.

What is a Counter Flow Asphalt Plant?

What is a Counter Flow Asphalt Plant?

A counterflow asphalt plant is an innovative facility designed to produce high-quality asphalt mix. It operates on the principle of counterflow, where the heating and mixing of aggregates and asphalt occur in separate compartments. This design offers several advantages, such as improved energy efficiency and reduced emissions.

How Does a Counter Flow Asphalt Plant Work?

In these plants, the aggregates enter the plant at the opposite end of the exhaust gases. This arrangement allows for a gradual increase in temperature and improved mixing. The heated aggregates move towards the mixing chamber, where they are combined with hot asphalt to produce a homogeneous mix.

Advantages of Counterflow Asphalt Plants

Advantages of Counterflow Asphalt Plants

Energy Efficiency

Counterflow asphalt plant saves energy by using the exhaust gases to preheat the aggregates. This reduces fuel consumption and operational costs.

Reduced Emissions

Since the heating area and mixing area are separated, counterflow plants emit fewer pollutants, making them environmentally friendly.

Quality of Asphalt

Counterflow design ensures the consistency and quality of the asphalt mix according to industry standards.

Common Applications

Common Applications

Counterflow asphalt plants are versatile and can be used in many construction projects. They are generally used in the construction of highways, airports and large-scale infrastructure projects.

Key Components of a Counterflow Asphalt Plant

Key Components of a Counterflow Asphalt Plant

All key components of counterflow asphalt plant such as:

Drying Drum

The drying drum is where aggregates are heated and dried before they enter the mixing chamber.

Mixing Chamber

In the mixing chamber, hot asphalt and aggregates are blended to create the final asphalt mix.

Exhaust System

The exhaust system is responsible for capturing and cleaning the gases produced during the process, reducing emissions.

Control Centre

The control centre manages the entire plant, ensuring the process runs smoothly and efficiently.

Choosing the Right Counterflow Asphalt Plant

Selecting the right counterflow asphalt plant depends on various factors such as:

Capacity and Throughput

The plant’s capacity should align with the project’s requirements to ensure timely completion.

Fuel Options

Consider the availability and cost of fuel options, as this will affect operating costs.

Environmental Compliance

Ensure the plant complies with environmental regulation and emission standards.

Installation and Maintenance

Installation and Maintenance

Proper installation and regular maintenance are essential for the efficient operation of a counterflow asphalt plant. Regular inspections and maintenance will prolong the plant’s lifespan and maintain its performance.

Counterflow vs. Parallel Flow Asphalt Plants

Compare counterflow and parallel flow asphalt plants to understand their differences and decide which is right for your project needs.

Case Studies: Real-world Applications

Explore real-world examples of how counterflow asphalt plants have improved construction projects, highlighting their efficiency and cost-effectiveness.

Counterflow Asphalt Plant Manufacturers

Discover reputable manufacturers of counterflow asphalt plants, ensuring you choose a reliable and high-quality product.

Cost Considerations

Examine the costs associated with purchasing, operating, and maintaining a counterflow asphalt plant to make an informed investment decision.

Future Trends

Stay updated on the latest developments in counterflow asphalt plant technology and their potential impact on the industry.

Conclusion

Conclusion

Counterflow asphalt plants have transformed the way asphalt is produced, offering enhanced energy efficiency, reduced emissions, and consistent quality. Choosing the right facilities and following maintenance procedures is crucial to the success of your construction.

Frequently Asked Questions

Yes, counterflow asphalt plants come in various sizes to accommodate projects of all scales.

Counterflow plants separate the heating and mixing zones, resulting in fewer emissions.

With proper maintenance, a counterflow asphalt plant can last for many years.

Operating these plants may require specific training, which can be provided by the manufacturer.

Some models are designed to run on alternative fuels, promoting environmental sustainability.

Operating temperatures vary, but they are carefully controlled to achieve the desired asphalt mix.

Yes, their energy efficiency and reduced emissions often result in long-term cost savings.

Many modern counterflow plants come equipped with advanced automation for efficient operation.

Yes, manufacturers often offer customization options to meet project-specific needs.

These plants produce fewer emissions, helping to reduce the environmental impact of construction projects.