In today’s rapidly evolving construction industry, automation plays a vital role in increasing productivity, ensuring quality, and minimizing human error. One of the most significant advancements in this domain is Cybermix Automation—a smart, intuitive, and reliable control system designed specifically for bitumen batch mix plant.

Cybermix brings a new era of precision and control to asphalt production, enabling operators to optimize plant operations and meet demanding infrastructure requirements. Here’s why Cybermix Automation is revolutionizing the way asphalt is mixed.

What Is Cybermix Automation?

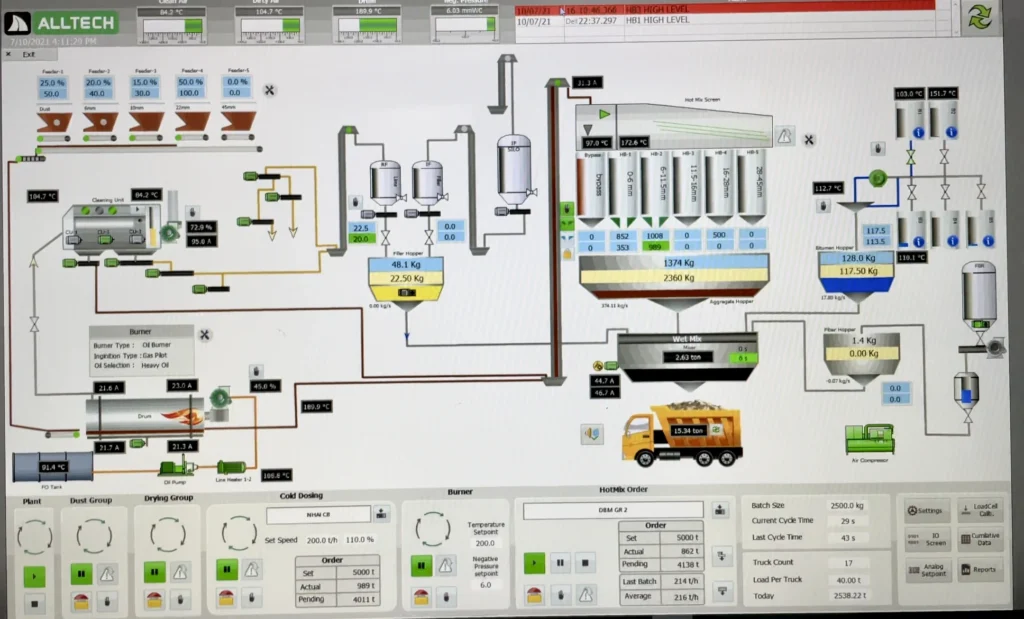

Кибермикс is a next-generation asphalt mixing plant control system that seamlessly integrates advanced software, digital sensors, and real-time data analytics. It is engineered to manage all key processes in an asphalt batch mix plant, including:

- Cold aggregate feeding

- Drying and heating

- Bitumen and filler dosing

- Mixing cycles

- Storage and dispatch

This intelligent automation system ensures that each batch is produced with unmatched consistency, accuracy, and efficiency.

Key Benefits of Cybermix Automation

1. Precision Control Over Asphalt Mix Design

Cybermix allows operators to pre-program and fine-tune mix recipes, ensuring:

- Exact material proportions

- Consistent batch quality

- Compliance with MORTH, NHAI, and other global standards

2. Real-Time Monitoring and Alerts

Equipped with smart sensors and a user-friendly interface, Cybermix provides:

- Live process data and trends

- Instant alerts for faults or inconsistencies

- Preventive maintenance prompts to reduce downtime

3. User-Friendly Interface and Remote Access

Cybermix features an intuitive touchscreen interface with easy-to-navigate dashboards. It also supports remote monitoring, allowing supervisors to track production even when off-site.

4. Enhanced Production Efficiency

By automating repetitive tasks and optimizing cycle times, Cybermix:

- Reduces manual errors

- Increases throughput

- Saves energy and material costs

5. Customization and Integration

Cybermix is scalable and compatible with additional modules such as:

- RAP (Reclaimed Asphalt Pavement) integration

- Fiber Dosing Unit

- Foam Bitumen System

- Coal-fired burner and multi-fuel burner automation

This allows plant owners to future-proof their setup and expand functionality as needed.

Why Choose Cybermix for Your Asphalt Plant?

Whether you’re operating a stationary or mobile asphalt plant, Cybermix adapts to your needs. Its data-driven approach и digital control bring the kind of operational transparency and flexibility that is critical for modern infrastructure projects.

From national highways and airport runways to rural roads and smart cities, Cybermix Automation delivers quality you can measure, track, and trust.

Заключение

As infrastructure projects demand higher quality and faster execution, the need for smarter asphalt production becomes unavoidable. Cybermix Automation empowers asphalt plant operators with digital control, enhanced accuracy, and optimal efficiency—paving the way for better roads and smarter construction practices.

If you’re looking to upgrade your asphalt plant, make Cybermix the foundation of your automation journey.