Introduction

Selecting the appropriate capacity for your asphalt batch mix plant is a critical decision that directly impacts the efficiency, cost-effectiveness, and productivity of your road construction projects. These plants are vital for producing high-quality asphalt used in highways, expressways, airports, and other infrastructure projects across India. For contractors, civil engineers, and plant operators, understanding your production needs and aligning them with the ideal plant capacity is essential. This comprehensive guide outlines the key factors to consider when choosing the right capacity for your asphalt batch mix plant, ensuring optimal return on investment (ROI) and operational performance.

What is Asphalt Batch Mix Plant Capacity?

The capacity of an asphalt batch mix plant is measured in tons per hour (TPH), indicating the maximum amount of hot mix asphalt the plant can produce per hour under ideal conditions. Common capacity ranges include:

- 80–100 TPH: Suitable for smaller road construction projects.

- 120–140 TPH: Ideal for medium-sized projects with moderate traffic.

- 160–180 TPH: Perfect for national highways and larger infrastructure.

- 200+ TPH: Designed for high-demand projects like expressways, airports, or export-oriented production.

Choosing the right capacity depends on the type, volume, and frequency of your projects.

Key Factors to Consider When Choosing Capacity

1. Analyze Your Project Requirements and Asphalt Volume

Start by evaluating your current and upcoming projects to determine your asphalt production needs. Ask yourself:

- How many kilometers of road will you construct?

- What is the asphalt thickness and layer design?

- How many tons of asphalt mix are needed daily?

- Are you handling single or multiple projects simultaneously?

For example, if your project requires 1,000 tons of hot mix asphalt per day and you operate the plant for 10 hours daily, a plant with at least 100 TPH capacity is necessary. For high-volume projects like expressways or tight timelines, a 160–180 TPH plant may be more appropriate.

2. Evaluate Available Space and Site Layout

Higher-capacity asphalt batch mix plants require significant space for installation and operation. Consider:

- Site accessibility for trucks and loaders

- Storage space for aggregates, bitumen, and filler

- Room for silos, baghouses, fuel tanks, and control cabins

- Compliance with environmental regulations and buffer zones

In urban or constrained spaces, mobile or compact modular asphalt plants can deliver high productivity with a smaller footprint, making them a practical choice.

3. Consider Your Budget and Cost Efficiency

The initial investment for an asphalt batch mix plant varies by capacity, with larger plants requiring:

- Higher upfront costs

- Increased energy and fuel consumption

- More space and structural support

- Greater operating and maintenance expenses

However, larger-capacity plants often offer a lower cost per ton of production when used efficiently, providing better long-term value. Balance your immediate project needs with long-term goals to select a plant that maximizes ROI.

4. Think Long-Term: Expansion and Flexibility

Consider your business growth over the next 2–5 years. Key questions include:

- Will you take on larger or more frequent projects?

- Are you planning to work with public infrastructure departments or the National Highways Authority of India (NHAI)?

- Do you anticipate exporting hot mix asphalt?

Choosing a plant with slightly higher capacity than your current needs allows for future expansion without costly upgrades. Opt for modular plants that can be enhanced with add-ons like:

- Reclaimed Asphalt Pavement (RAP) systems

- Additional bitumen storage tanks

- Hot mix storage silos

- Fiber dosing units

- Pollution control units

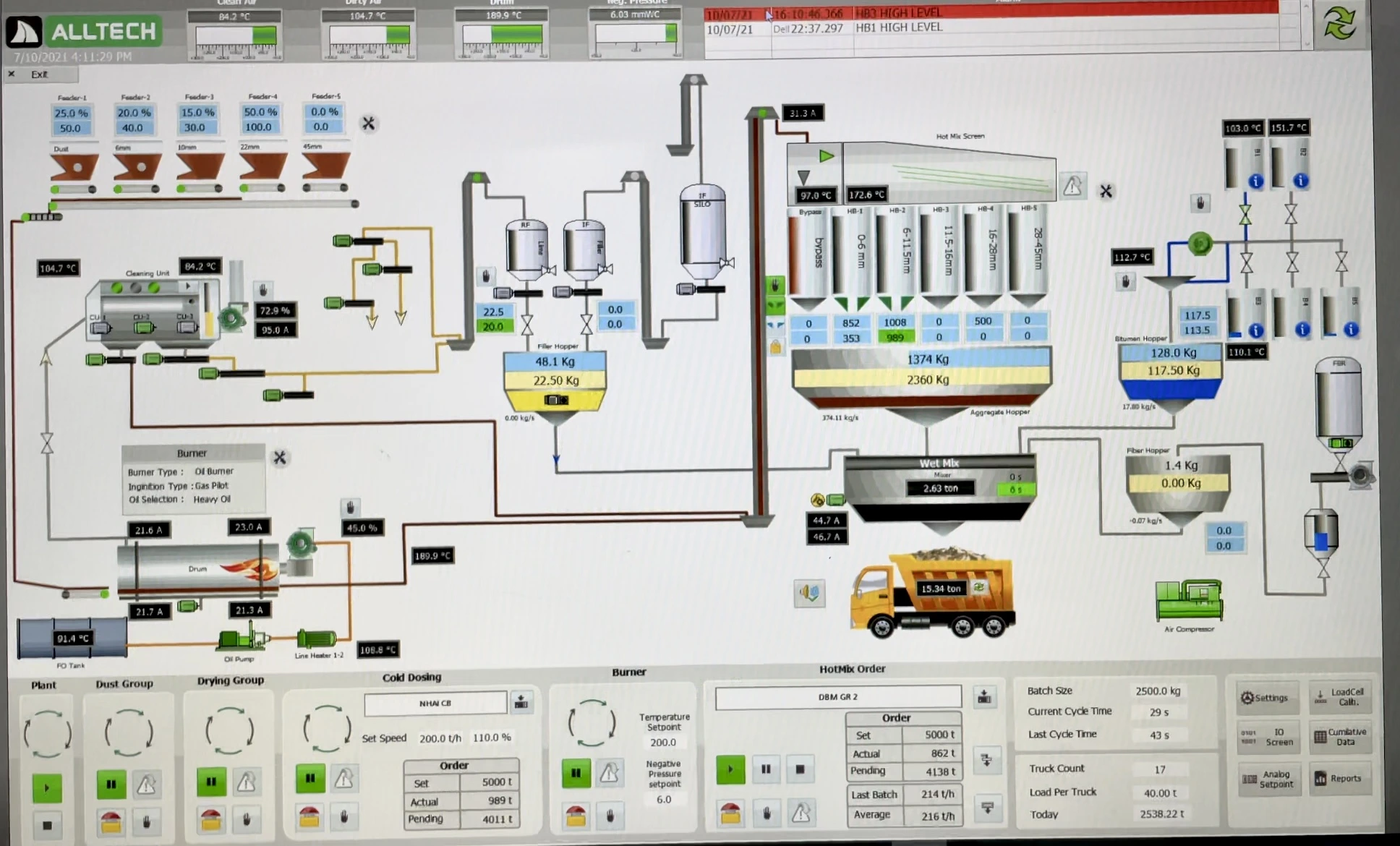

5. Assess Production Efficiency and Mix Quality

Capacity affects not only output but also mix quality and operational efficiency. A plant operating at its optimal load ensures consistency in:

- Aggregate gradation

- Bitumen content

- Mixing temperature

- Dust control

Overloading a low-capacity plant can reduce mix uniformity and shorten equipment lifespan, while underutilizing a high-capacity plant increases costs per ton. Use advanced control systems, SCADA-based software, and automation to optimize productivity while maintaining quality.

6. Environmental Compliance and Energy Use

With strict environmental regulations in India, your plant’s capacity must align with its pollution control systems. Evaluate:

- Fuel efficiency of the dryer drum and burner

- Baghouse capacity and dust filtration efficiency

- Emission controls for stack and exhaust

- Noise levels during peak operation

Ensure compliance with local and international environmental standards. Larger-capacity plants should include eco-friendly features like warm mix asphalt compatibility, energy-efficient burners (e.g., coal-fired, LDO, or natural gas), and emission monitoring systems.

7. Match the Plant Type with Your Capacity Needs

Select the plant type based on your capacity and mobility requirements:

| Plant Type | Best For | Common Capacities |

|---|---|---|

| Stationary Asphalt Batch Mix | Long-term projects, large-scale production | 120–320 TPH |

| Mobile Asphalt Batch Mix | Projects requiring frequent relocation | 80–180 TPH |

| Containerized Modular Plants | Export or remote locations with space constraints | 100–200 TPH |

| Counterflow Drum Mix Plants | Continuous production and high efficiency | 90–200 TPH |

Conclusion

Choosing the right capacity for your asphalt batch mix plant is a strategic decision that should reflect your current project requirements, future growth plans, and commitment to sustainability. By evaluating project needs, available space, budget, expansion potential, production efficiency, environmental compliance, and plant type, you can select a plant that maximizes productivity, minimizes downtime, and ensures long-term profitability. Consult with trusted asphalt plant manufacturers in India, such as Atlas Industries or Kaushik Engineering Works, to explore configuration options, upgrades, and after-sales support to get the most from your investment.